WHAT IS A FLOW CONTROLLER?

A flow controller is an advanced technology specifically designed to regulate and manage the flow rate of water in marine applications, such as superyachts and cruise ships. These flow controllers ensure optimal water flow, irrespective of pressure fluctuations, delivering consistent and controlled quantities of water.

A flow controller is an advanced technology specifically designed to regulate and manage the flow rate of water in marine applications, such as superyachts and cruise ships. These flow controllers ensure optimal water flow, irrespective of pressure fluctuations, delivering consistent and controlled quantities of water.

Installed within the marine water systems, flow controllers provide a range of benefits tailored to meet the unique demands of maritime environments. They contribute to the sustainability of onboard operations by promoting water and energy conservation. By efficiently controlling the water flow, less water is used and flow controllers help reduce wastage and optimize resource usage, resulting in significant cost savings for superyachts and cruise ships.

One of the key advantages of flow controllers in marine applications is their ability to eliminate fluctuations in pressure and temperature. This ensures a comfortable and stable experience for passengers and crew members. With a reliable and consistent water flow, onboard activities, including showers and taps, can be enjoyed without interruptions or sudden changes in temperature.

Flow controllers also play a vital role in system stabilization, ensuring that sufficient water pressure is maintained throughout the vessel. This enables multiple draw-off points to function simultaneously, providing ample water supply for various operations onboard.

In the marine industry, flow controllers are an essential component for achieving optimal comfort, efficient water management, reducing energy consumption, and maintaining convenience onboard superyachts and cruise ships. Their reliability, performance, and adherence to industry standards make them a trusted choice for marine applications.

How does it work?

Truly independent of pressure! While the idea is simple, the technology behind it is complex: The flow controller is manufactured using a special engineering plastic and a spring element made from high-quality steel. Together, these components make up a strong and precise regulator mechanism.

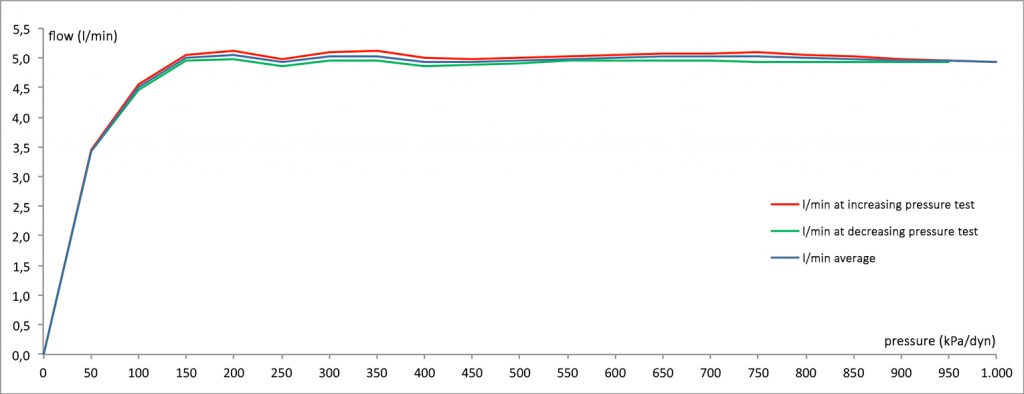

Marine Flow products always adapt immediately to existing water pressure and any fluctuations thereof. This response capacity ensures the flow rate remains constant in a broad, dynamic range of pressure situations.

The flow controller functions immediately and with no need for calibration. In short: The flow controller delivers a constant flow rate, always and everywhere.

Discover how the flow controller functions with our interactive animation. (soon)

Pressure-independent flow controllers:

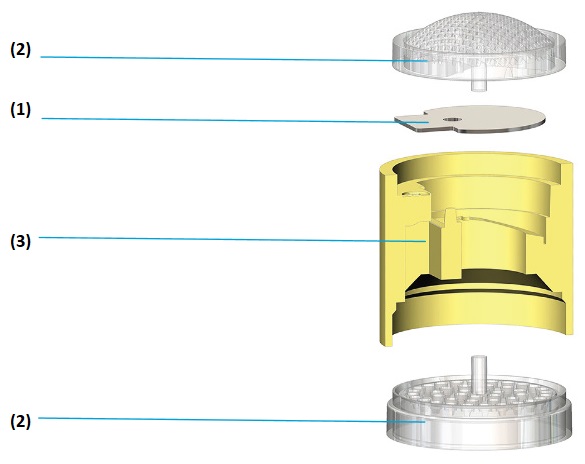

- The valve is made of very high-quality and precise spring steel. It is flexible yet strong and constitutes half of the flow control principle of Marine Flow. The valve mechanism and the housing respond immediately to pressure differences, resulting in a constant flow. The steel is custom-made with an utmost precision of thousands of millimeters.

- Two specially designed filters protect the control mechanism. The large openings in the bottom sieve ensure that the flow restrictor remains clean from the inside, as no dirt can accumulate inside. Most particles stay on top, and any particles that do get inside are also expelled.

- The second integral part of the flow controller is the housing, made from high-quality plastic that ensures continuous and precise operation. The housing is produced by specialized injection molding with the smallest possible tolerances. The injection molding process is continuously monitored and adjusted as necessary. This guarantees the continuity of quality and performance.During production, the products are continuously and extensively tested to ensure pressure independence and quality consistency in their operation.

Case study:

Fluctuating shower water temperature in a fresh water system

** The problem:

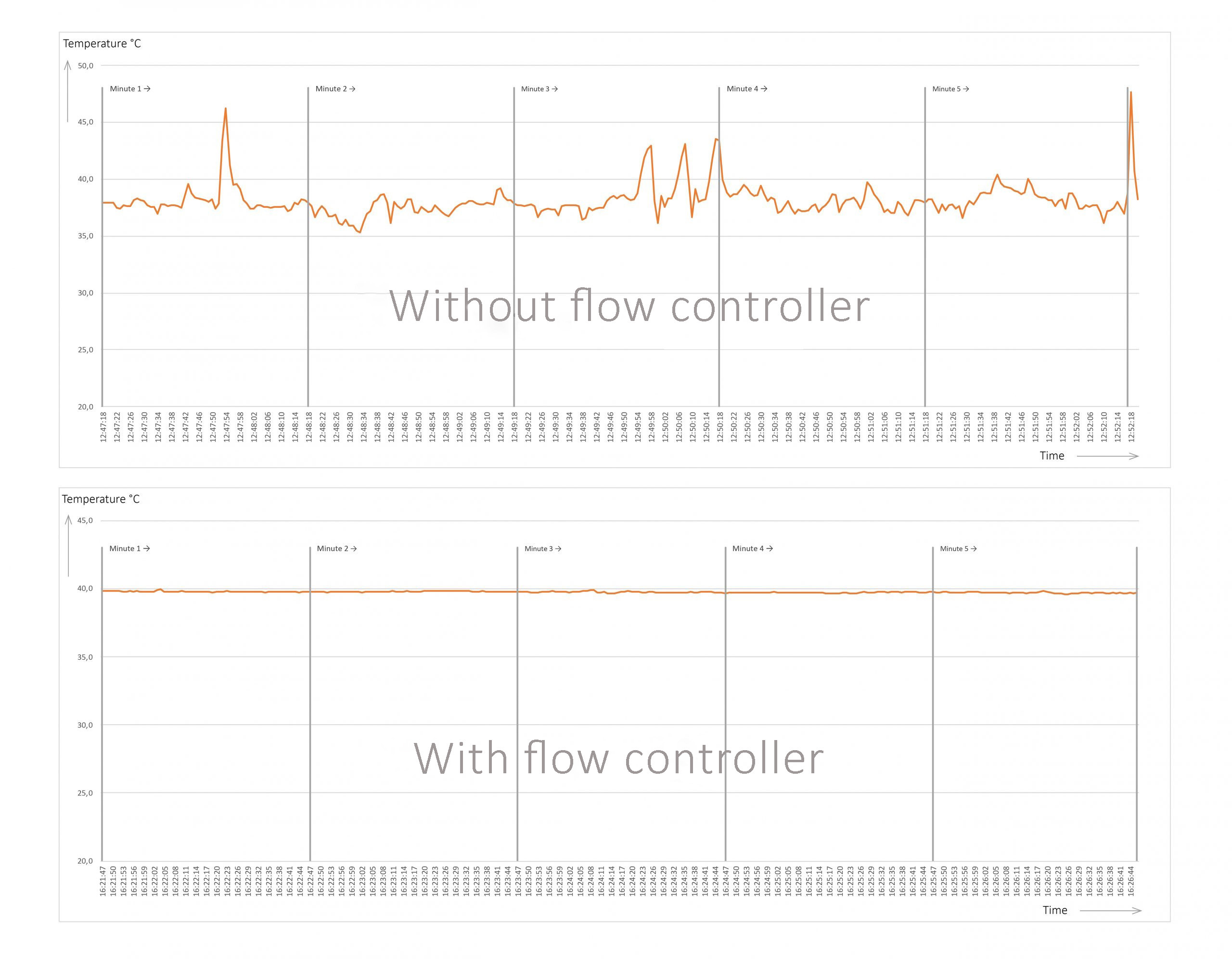

A 124 mtr Rein cruiser had reported issues with sudden temperature fluctuations in shower water. Tests showed that the water temperature out of the shower head deviated over 12.0 ℃ in a 5-minute time span. This caused discomfort and risks to guests.

The solution:

To install the pressure independent flow controller, MF 1P inline into the cold and hot water supply pipes to the shower mixer. Alternatively, you have the option to use the MF connect and connect-S instead of the inline version.

Results:

No more discomfort nor risks for the guests regarding temperature deviations in the shower. Temperature fluctuations were reduced to less than 0,4 ℃! Comfort and safety have increased thanks to a much more consistant temperature, as well as a constamt quantity of water. Take a look at the results of the measurements with and without the flow controller.

Specifications and certifications:

Constant flow: standard versions of : 5.0 | 7.8 litres/min and any modular combination within the Cartidge range.

Operating pressure range: 200-1.000 kPa/dyn

Materials: synthetic material, stainless steel

Certified temperature tolerance range: hot water (90°C) Certified for functionality of pressure independence: yesCertified for drinking water safety: yes

The constant flow property is achieved by the built-in pressure independent flow regulator Within the mentioned pressure range the flow reviation is approximately 2%. Our flow controllers comply with the most important European standards for both durable and reliable pressure independence (Dutch Kiwa Evaluation Guidelines BRL-K635/03) and, built-in to several housings, to drinking water safety (Kiwa ATA, WRAS, ACS, W270, KTW).

Patents on the Flow Controller working principle have been grated in 29 countries.